3D printing house likely to be the terminator of shanty town

3D printed houses are no longer just TV news. They are likely to be the terminator of one of humanity's biggest headaches, the shantytown. Between now and 2050, humanity will have the largest migration in history. For the first time in human history, with so many people living in cities, affordable housing for urban dwellers will be a pressing problem. Thirty major megacities (with a population of more than 10 million, and the top ten cities with a population of more than 20 million) will bear the brunt of the ongoing mass migration. Eight of the ten cities are in Asia and the other two are in North America.The ten cities will also face the most serious problems of shantytowns.

Eight of the ten cities are in Asia and the other two are in North America. Currently, 3.6 billion of the world's 7 billion people live in cities, with another 864 million (24.5%) living in shantytowns.According to the UN's world urbanization outlook, the number of urban dwellers will almost double from the current 3.6 billion to 6.3 billion by 2050, while 2.1 billion people will live in shantytowns.Due to the continuous expansion of shantytowns, rapid urbanization, economic stagnation and depression, high unemployment, poverty, natural disasters and social contradictions will pose serious threats to the whole society.Many things are not done now, and it will be too late to do them later.Rapid printing of cheap living space may be part of the solution to the problem of population living caused by rapid social change.

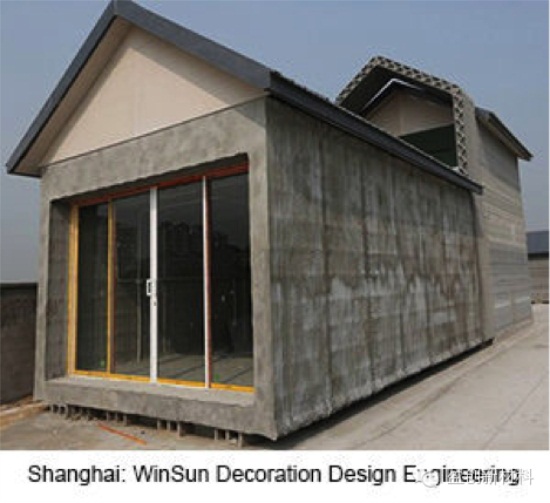

In theory, 3D printing is the perfect solution to replace shantytowns. Most of the construction is done by automated robots. The cost of the building mentioned below is fairly low: $4,500 per 2,100 square feet.“ Construction is one of the most polluted and least efficient industries,” DUS architect Hedwig Heinsman said, “ Using 3D printing, zero waste, reduced transportation costs and the fact that all materials can be melted down and recycled, will revolutionize the way we build cities.”There are many obstacles to large-scale 3D printing houses at present, among which the main problems are that there is no existing building regulation and related behaviors. It uses 10 times as much electricity as it does in a factory and has not yet found the materials that are ideal for weight strength and durability.Taken as a whole, these are minor obstacles, but piling up will also prevent 3D printing from bringing good news to those living in squalor. In Shanghai, Amsterdam and Los Angeles, 3D printed homes are becoming formal businesses with formal plans and road maps. Shanghai: Yingchuang decoration and design engineering Co.,Ltd. is located in Shanghai. CEO Ma used large 3d printed to build 10 buildings within 24 hours by recycle materials. Yingchuang uses a large 3D printer 150 meters long, 10 meters wide and 6 meters high to print every part of a building, from large concrete slabs to internal cross supports. “ We buy printer parts from overseas and assemble them in a factory in Suzhou.” President Ma said. “The new 3D printer is cheap and environmentally friendly.” To cut costs, invesco USES concrete frames made from recycled construction waste, industrial waste and fiberglass. Each house is about 2,100 square feet.Amsterdam: is DUS 3D printing the future of home building? In Amsterdam, DUS is testing the technology for the first time. “ The architects have been working on the site for three weeks,” InHabitat reported, “ A 3-meter-high corner model has been built for their future house. The entire model is printed and weighs 180 kilograms. “This is part of the house, and over the next three years, the pieces will be pieced together like lego blocks into a traditional Dutch triangulation house with 13 rooms.”It's just that the hand-fired brick will look like plastic made by computer software. “ At the heart of the process is KamerMaker, a large, open-source home 3D printer made by Ultimaker of the Netherlands. It uses the same principle as extruding molten plastic layer by layer, only 10 times larger. Print from desktop level gadgets to 6x6x11 feet of large prefabricated parts.” Los Angeles: Behrokh Khoshnevis, a professor at the USC Viterbi School ofEngineering at the university of southern California, is developing a technology that automatically builds full-size city buildings: Contour Crafting. Khoshnevis, a professor of industrial systems engineering and urban and environmental engineering, is developing a machine that can build full-size urban buildings in a day.His goal was to print the entire building.Khoshnevis is also the director of the rapid automation building technology center, which is developing technology to make the entire building, including water, electricity and air conditioning, in 24 hours.Ending shantytowns is the promise of 3D printed buildings.