Yingchuang Ma Yihe: 3D printing creates more beautiful building

2014 Shanghai green building materials exhibition was held in Shanghai new international Expo center. In this exhibition, a large number of green building materials have been brought together, leading the green building trend and spreading the knowledge of green building. At the exhibition, Sina real estate interviewed the chairman of Shanghai Yingchuang Decoration Group Co., Ltd.

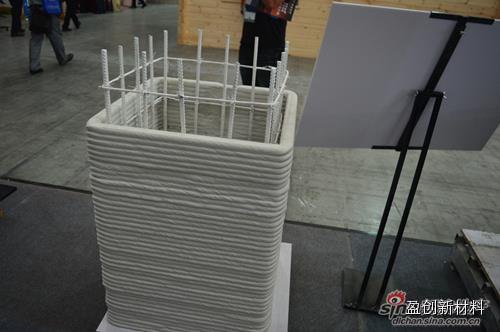

Sina: The use of 3D printing in architecture is the world's leading technology. Ying chuang's 3D architecture at the exhibition gave us an intuitive impact. What are the leading technologies in 3D printing?

President Ma: Yingchuang Decoration Group has developed for 12 years since its foundation. The company has accumulated a lot of experience in 3D printing, and has developed many new 3D printing technologies, which can be used in the construction of various special-shaped structures.

Its four technologies are leading worldwide. First is our universal ink concrete technology, 3D printing technology develops very fast, but use what kind of material as the printing ink, has always been a 3D printing technologies into one of the problems of building. No matter which kind of stone you use, you need to develop natural stone, which is a green technology. Yingchuang can take advantage of construction waste and sand and recycle it into 3D printing ink concrete, which not only solved the problem of ink materials, but also recycled a lot of construction waste. Second, the world's first continuous 3D printer, 3D printing is not as complicated as it might be. But continuous building printing is one of the difficulties, and this technology makes it possible to use 3D printing in buildings. The next building may require only one or two people, and a continuous 3D printer can be completed on site. The third is the world's largest 3D printer. The company has a 3D printer of 10x6.6x150m, which provides the possibility for future 3D printing on Bridges and high-rise buildings. In the end, Yingchuang has integrated 3D printing integration technology to meet the needs of various special-shaped buildings.

Sina: What changes can 3D printing bring to architecture?

President Ma: Recycling of construction waste and mine waste is a green and environmentally friendly material that would otherwise have produced a lot of carbon emissions. Now, they are no longer garbage, but a raw material for new buildings. 3D printing can overturn the current impression on construction sites. Traditional construction sites are noisy, dusty, heavy workload and long construction time. And the 3D printing on the spot completely uses dry method construction, almost no dust, greatly reduces labor and time cost. 3D printing can also be used in the process of controlling desertification, taking sand as the material to print the sand and sand structure, taking the sand control sand, and participating in the operation of greening China more clearly.

Sina: There may be some concerns about 3D printing. Does Yingchuang has other successful building cases?

Ma Yihe: In fact, 3D printing technology has been used in many buildings, such as Shanghai grand theatre, Expo center, phoenix TV tower, and Huawei factory in Shenzhen. We have worked with cofco in many projects. SRC (special glass fiber cement) can realize various heteromorphic structures. Beijing SOHO and our own 10 buildings in Zhangjiang hi-tech park have used very bold modeling designs. Then the 3D printing architecture can realize the integration of interior and exterior decoration and insulation and waterproof system. We have to implement a 1100 ㎡ villa projects tomson, as well as the G20 summit abnormity residential building of the project, which not only realizes the design complex pattern and the shape, the strength of the building itself, the thermal insulation performance is also very good, also greatly saves the cost. It can be said that 3D printing technology is the best way to achieve green building and can create better future buildings.