GlassFiber Reinforced Gypsum

GRG full name: GlassFiber Reinforced Gypsum

GRG is glass fiber reinforced gypsum board. It is a kind of special modified fiber gypsum decoration material, the casual sex of the modelling makes it become the first choice that demands individuation architect. Its unique material structure is sufficient to withstand the damage, deformation and cracking caused by external environment.

GRG products is to use superfine crystallization of gypsum (improved ɑ gypsum) as the basic material and special continuous rigid reinforced fiberglass. We develop proprietary additives (conform to the requirements of the international additives), through special process on the mould of laminated pre-cast type new decoration material, the comprehensive performance has reached the international quality standards.

The surface of the product is smooth and white, the material surface is smooth and fine, the whiteness is more than 90%. It can be bonded with various coatings and finishes, forming excellent decorative effect and environmental protection without any harmful elements. This kind of material can be made into various planar boards, various functional products and various artistic styles, which is the most popular updating product in the world of building materials decoration.

GRG core advantages

1. Infinite plasticity

The product is transformed into a production drawing according to the drawings of the project, and the mould is made first, so the fluid precast production mode can be made into any shape. Because of people's demand for architectural aesthetic art, the designer has carried out imaginative and innovative design, which can be difficult to realize without corresponding architectural decoration materials. The plasticity of the GRG/C product's arbitrary shape has realized the seamless connection of the product and is the perfect realization of the designer's dream. The service life of the product is more than 200 years.

2.Can breathe, natural adjust indoor humidity:

GRG plate is a kind of plate with a large number of microporous structure. In the natural environment, the porous body can absorb or release water. When the indoor temperature is high and the humidity is small, the plates gradually release the moisture in the micropores. When the indoor temperature is low and humidity is large, it absorbs moisture from the air. This release and breath forms the "breath" effect. The circular change of moisture absorption and release of moisture can regulate the indoor relative temperature and create a comfortable microclimate for work and living environment.

3.Light weight and high strength:

The standard thickness of the GRG product plane section is 3.2 to 8.8MM (special requirements can be thickened), and the weight of the main building is only 4.9 to 9.8KG, and the weight of the main building and the load of the component can be reduced. GRG products are of high strength, breaking load greater than 1200N, exceeding the international JC/T799-1998 (1996) decorative plasterboard breaking load 118N of 10

4. Good sound effect

The test showed that the GRG material was 4MM thick, through 500Hz 23d100Hz 27db; Air dry weight 1.75, accord with professional acoustical reflex request. After good design, the sound absorption structure can be formed to achieve sound insulation and sound absorption.

GRG advantages

1. No deformation

Because GRG gypsum material of glass fiber without any corrosion effect, coupled with wet and dry shrinkage rate is less than 0.01%, thus can ensure that the product performance is stable, durable, no crack, no deformation, long service life.

2. Light weight

The standard thickness of the plane part of GRG product is 3.2 to 8.8MM (special requirements can be thickened). The weight of each square meter is only 4.9 to 9.8KG, which can reduce the weight of the main building and the load of the components.

3. High strength

The experimental results show that the fracture load of GRG products is greater than 1200N, which is 10 times greater than that of the fracture load of gypsum board in international JC/ T799-1998 (1996).

4.Breathe

GRG plate is a kind of plate with a large number of microporous structure. In the natural environment, the porous body can absorb or release water. When the indoor temperature is high and the humidity is small, the plates gradually release the moisture in the micropores. When the indoor temperature is low and humidity is large, it absorbs moisture from the air. This release and breath forms the "breath" effect. The circular change of moisture absorption and release of moisture can regulate the indoor relative temperature and create a comfortable microclimate for work and living environment.

5. Fireproof

The GRG material belongs to class A fireproof material. When the fire occurs, it can release water equivalent to 15 to 20 percent of its own weight in addition to the flame retardant, which can greatly reduces the fire surface temperature and reduce the fire loss.

6.Environmental

GRG materials have no smell, and the radionuclide limit conforms to the standard of class A decorative materials specified in GB6566-2001. And it can carry on the recycling, belong to green environmental protection material.

7. Good acoustics

The test showed that the GRG material was 4MM thick, through 500Hz 23d100Hz 27db; Air dry weight 1.75, accord with professional acoustical reflex request. After good design, the sound absorption structure can be formed to achieve sound insulation and sound absorption.

8.Short working cycle

It takes only 30 minutes for GRG products to die, and only 4 hours in dry time. Therefore, the construction period can be greatly shortened.

9.Convenient Construction

GRG can be made according to the designer's design and can be produced and segmented. Site processing performance is good, the installation is quick, flexible, can carry on the large area seamless and tight, form the complete modelling. In particular, the hole, arc, corner and other details can ensure no error.

10. Smooth and fine material surface

The whiteness is more than 85%, and can be well bonded with various coatings and finishes, forming excellent decorative effect.

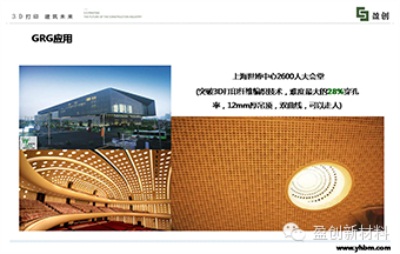

GRG Application

Application

Acoustic engineering projects such as theatre, lecture hall, exhibition center and stadium.

Hotel, sales office, club (KTV, SPA, bath, etc.)

Comprehensive commercial body, high-end shopping malls, such as wanda plaza, SOHO;

KA customers (important customers), headquarters enterprise expansion projects such as Huawei, sany heavy industry factory, R&D center.