Yingchuang 3D printing architecture appeared in Suzhou, printing the villa within one day!

Recently, several buildings using 3D printing technology were unveiled in Suzhou. The building includes a villa of about 1,000 square meters, a five-story residential building and a simple exhibition hall. The walls of the building are painted by large 3D printers. After the buildings were made with 3D printing technology, a house could be printed in a day.

At the scene

In addition to the steel structure, the whole villa is printed

The house, which is about 1,000 square meters, is printed except for the steel structure. Looking closely at the wall, it is found that there is a wall of bricks outside, and inside it is a wall of threads that are layered like a noodle. Each "noodle" is a tightly knit, seemingly organic whole. In order to keep warm, the whole wall has space, not filling. It feels a little similar to the feel of the concrete wall. Although the hand feels very rough, the wall surface is very solid, the hand does not leave a bit of cement powder residue.

Behind the scenes

The 3D printer prints out the building components and then assembles them.

The "printer" is 6.6 meters high, 10 meters wide and 32 meters long. The floor covers an area of a basketball court with a height of three stories. The width of the printed material can only be 1.2 meters, but the length can be infinite. According to computer design drawings and plans, the computer controls a huge nozzle to spray "ink". The sprinkler head is like a cream mounted, the ink is in "Z" line, layer by layer, quickly built a high wall. After that, the wall and the wall can also be built like building blocks, reusing reinforced concrete for secondary "printing" perfusion, into a whole. Within 24 hours, 10 buildings of 200 square meters can be printed.

The printing ink raw materials are mainly construction waste, industrial waste and mine tailings. Other materials are mainly cement and steel, as well as special additives.

These printed buildings are built with internal steel structures, which are then printed out by a 3D printer and then assembled. A 1, 000-square-meter two-story villa, printing 1 day, assembling 2 days, 3 workers are enough.

Merchants

3D printing cost low wall strength, good insulation performance

The biggest advantage of 3D printing architecture is energy saving and environmental protection and material saving. Because 3D printing buildings do not produce any dust or construction waste. Using 3D printing technology, the construction materials can be reduced from 30% to 60%, and the construction period is reduced by 50% to 70%. Construction costs can be saved at least 50%. And customers can customize their home and house styles.

Because the walls are made of cement, a small amount of steel and some construction waste, many people doubt the strength of the wall. For this reason, the material supplier said that because of the special additives added in the printed material, the strength of the 3D printed wall is five times that of the ordinary wall. In addition, the hollow space in the center can be filled with various thermal insulation materials, so the building insulation effect of 3D printing will be particularly good.

At present, 10 sets of 3D printing villas with 3D printing villas are displayed.

Reading extension:

How big is 3D printing? Look at these finished products!

3D printing photo studio: It takes only 10 minutes of 3D scanning and a few hours to get an entity portrait. Use 3D printing technology to print doll souvenirs.

3D printing gun: In the past few days, a CAD file for the world's first 3D printed handgun has been downloaded more than 100,000 times on the Internet, causing panic. The reason people panic is that, in this sense, a 3D printer can make a gun, and how can it be secured?

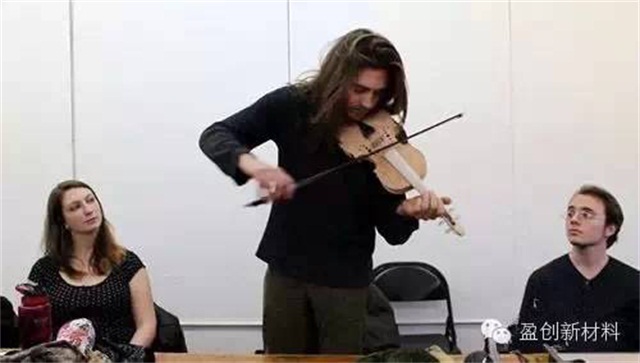

Semi-processed 3D printed violin: Abroad, the world's first 3D printed violin was born, but it was actually a semi-finished product. When alex Davis, the violinist, made the main part of the cello in 3D, he and his team finished the second half of the production with newspaper and glue plastic.

Printing stem cells: Stem cells, also known as origin cells, are a class of pluripotent cells with self-replicating capabilities. Under certain conditions, it can differentiate into many functional cells. It is a kind of immature cell, which has the potential function of tissue organ and human body.

Replace the bone: In fact, there have been a lot of reports about the application of 3D printing technology to medical care, which is the biggest benefit for human beings. The idea of printing human organs has been in practice, and printing organs is still a dream. However, it has been successful in some cases, such as the replacement of the skull, and nearly 75 percent of the perfect reducibility makes 3D printing look forward to future maturity.