Material Language: The building materials revolution in the digital age

Early in 1901, at a meeting in Hull House, Chicago, American architect Wright Wright read an article titled "the art of the machine." He proposes that the machine tool will become the architect's powerful extension, and the architect's role in architectural design will change. He argued that architects should learn about new technologies, new machines, and more attention to the unspeakable expressiveness of building materials under these new technological conditions. Thirty years later, architect corbusier, in his book "going to new buildings", imagined that with the development of social industrialization, buildings could be precisely made like cars and airplanes.

However, more than a hundred years later, the emergence of digital technology has experienced the development of "manual processing", "traditional machine" and "CNC machine". With the addition of robots, 3D printers, quad-axis aircraft, CNC machines, laser cutting machines and 3D feet scanning, the new technology equipment is put into use in the construction design industry. In addition to inspiring more expressiveness in traditional building materials, the concept of "building materials" has become more generalized. "Building materials" may be understood from the point of view of "machine objects".

As the material foundation of building production activities, the development of material technology directly influences the spatial structure and artistic effect of the building. The construction of architectural design and materials are inseparable. Materials are the carrier of architectural design performance, and each design will eventually be applied to the use of materials. With the development of science and technology, the use of building materials out of the following thousands of years of traditional materials such as wood, stone, brick, earth framework, after that, the steel and cement concrete structure has been widely used. Nowadays, composite materials such as fiber and synthetic resin have become the speakers in the real world of architects. After both, the strong development of artificial intelligence ushered in the era of intelligent materials. Under the influence of digital age background, more and more new construction materials have been developed and promoted the new development of architectural design.

NO.1 Traditional material

As the operational object of the architect, the appearance of traditional materials can be traced back to the Stone Age. With the traditional construction method, traditional materials are still used today. But the development of science and technology and human needs has led to more and more demands on buildings. The use of traditional materials is difficult to satisfy the public. While the digital construction technology brings efficiency and creativity, the architect has achieved unprecedented height and precision in the processing and control of materials.

1. New technology of traditional materialsWooden roof

(Nine bridge country club interior effects)

(Indoor effect of nine Bridge Rural clubs)

(Manual erection process)

Japanese architect, winner of the pritzker architecture prize in 2014, in South Korea, le state, gyeonggi - nine bridge country club. He used the traditional wood for the interior, and the club's atrium and transparent glass provide a tall and transparent open space for the surrounding buildings and people. The structure is the wooden column and roof of the curve. The wooden pillars grow into the sky, and the roof is combined into a horizontal hexagonal grid.

Brick masonry

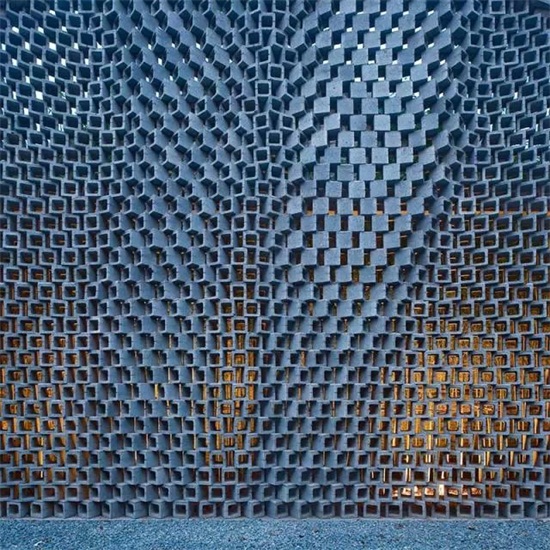

(Shanghai "five dimensional space" inside the creation alliance international j-office silk wall )

Located in the "five dimensional space" in Shanghai, China, the international j-office silk wall is designed with the cheapest hollow concrete block. To parameterize the grey degree of silk texture, translate it into the medium of wall masonry. By designing the construction tools and construction process of manual workers, the possibility of constructing low-tech parameters is realized. In the construction site, the template used by the artisans is the Angle positioning of the block, and the final wall presents the effect of soft and wrinkled fabric.

The same design method is also used in the design of lanxi pavilion, an intangible heritage park in chengdu, China. The combination of digital design and low-skill manual construction has special significance to the construction of digital architecture.

2. NC machining and construction

Robot brick

(In 2008, the construction of the Venice biennale, ROB built the Structural elements of the device.)

(In the 2008 Venice architecture biennale, ROB has built a Structural imf program)

In 2008, the construction of the Venice biennale, ROB built a Structural, and used a numerical control mechanism (6 axis robot) to explore the construction of traditional materials (bricks). The new control tools based on the raw material performance of the non-standardized components of the method are digital construction integration of traditional experience and modern techniques. The traditional combination of materials and machinery makes it easier for digital construction to be applied to actual production at the present stage. At the same time, in this process, the traditional mode of cooperation between architects and builders may be overturned. The interface between the two may no longer be the drawing, and the architect needs to be more involved in the construction itself, so that the subject autonomy of architecture can be improved at another level.

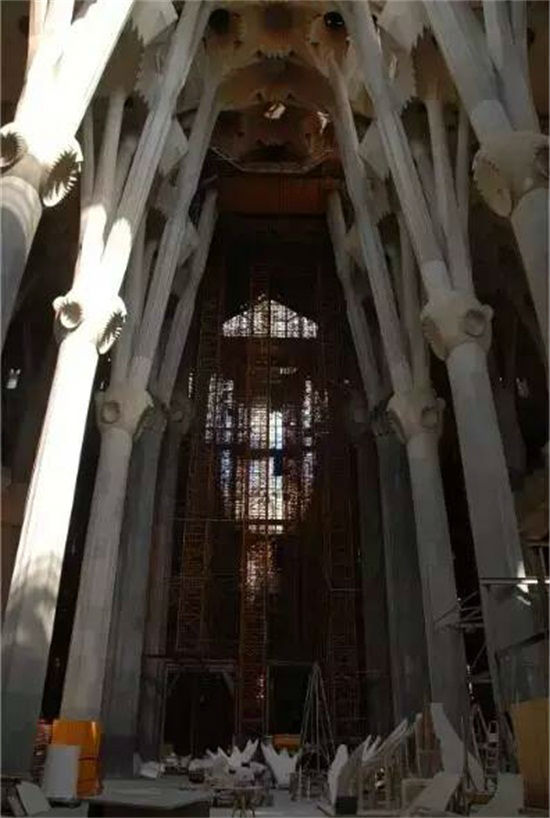

Mark Barichesfa rebuilt the Cathedral of the Holy Family

The holy family cathedral is the work of Spanish architect Antonio gaudi. It is located in the center of Barcelona in the Catalonia region of Spain. When gaudi died in 1926, the cathedral was only 15 to 25 percent complete. After the death of gaudi, the project was carried out in a series of twists and turns, with several architects involved in the project.

Until the 1980s, the church introduced modern tools such as computer-aided design and numerical control milling machines in the design and construction process. The process of obtaining proper building materials through the method of robot cutting is faster than ever. Mark Burry of New Zealand is a structural designer and researcher.

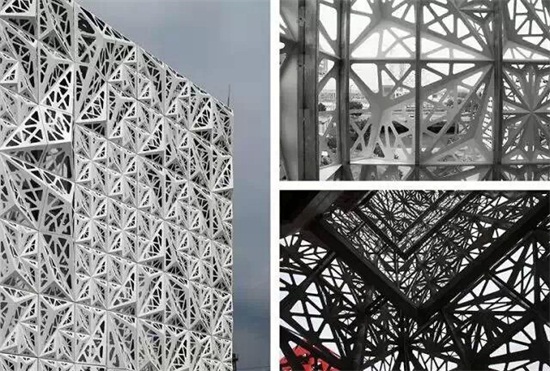

( Foshan art village building cuticle)

The vertical beam club uses digital construction technology to express unique spatial thinking. The design always emphasizes the combination of digital generation and construction technology, which shows the strength and structure of the material. Its works foshan art village, according to some local works of art, draw some characteristic artistic symbols, adopt the parameter chemical tools, carry on the new interpretation. The various patterns that are deducted, consider the requirements of sunshine, space use, etc., make corresponding choices, and process them through digital construction tools, and finally form a rich and changing epidermis.

The construction process first divides the epidermis, the structure of the epidermis adopts the simple vertical and transverse keel structure, and the size of the skin is determined according to the size of the keel. The material of the epidermis varies according to the specific location, as well as the structural requirements, or the use of metal, or the use of fiberglass. The epidermis was simplified and the most complicated epidermis was simplified to 5 standard modules. After determining the standard module, the processing plant is manufactured according to the processing technology of the material. Using the skin module of metal materials, the pattern is carved according to the plane shape, and then it is processed into aluminum plate by bending. After the factory is finished, carry out the label and carry it to the construction site for installation.

The use of computer design buildings can produce forms that were previously invisible, and forms that are not available in traditional methods can now be realized. At the same time, the processing of traditional materials by numerical control machinery makes people reflect: the process of constructing traditional materials has changed.

No.2 Composite material

Composite material is a material that is composed of two or more different properties through physical or chemical methods and is composed of new properties at the macroscopic (microscopic) level. The history of its use can be traced back to ancient times. The straw or wheat straw reinforced clay used in ancient times and the reinforced concrete that has been used for hundreds of years are composed of two materials. In the 1940s, the name of composite materials emerged from the development of fiberglass reinforced plastics (known as fiberglass) due to the needs of the aviation industry. After the 1950s, high strength and high modulus fibers, such as carbon fiber, graphite fiber and boron fiber, were developed. Aramid fibers and silicon carbide fibers emerged in the 1970s. These high strength, high modulus fibers can be combined with synthetic resin, carbon, graphite, ceramic, rubber and other non-metallic matrix or aluminum, magnesium, titanium and other metal matrix to form various composite materials.

The performance of various materials is complementary to each other, resulting in synergistic effect, which makes the composite material better than the original material and meet different requirements. Therefore, it can be said that the composite materials have unique skills.

Naturally, composite materials, due to their many advantages and special texture and texture, make it a favorite of digital construction, especially in 3D printing. The 3D printing technology requires a variety of features to take shape, from early resin to ABS, stainless steel and composite high-fiber concrete. Different composite materials have been developed and applied to different processes, and further exploration is still under way.

1. Robots operate composite materials

Argil

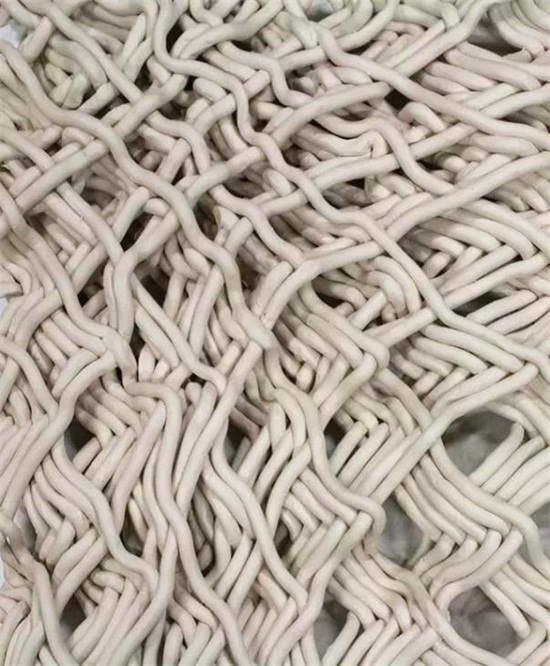

( Harvard University GSD robot clay printing )

First of all, all the traditional hand-made clay extrusions are transformed into robot movements. Robots can perform these actions more accurately, quickly and continuously. The construction of building facade or epidermal unit is achieved through the process of clay printing. Using traditional strip clay extruding as the basic language, weaving stack technology can achieve different cell network effects. The precise control of motion speed, extrusion speed, extrusion size and other aspects of the six-axis industrial robot also makes the material more diverse and precise.

Glass and carbon fibre

(2012-2013 years ICD/ITKE Research Institute robot preparation process)

(2013 - 2014 ICD/ITKE Research Institute robot preparation process)

Both research houses are made of fibers, and the pavilion is built with two large synchronized KUKA robots. They are responsible for wrapping the glass and carbon fiber around the thin steel frame. On the materials properties of fiber reinforced polymer and appropriate manufacturing method, on the basis of mature understanding team to make full use of the anisotropic material properties, thereby gaining fiber composite construction machinery manufacturing professional knowledge. The glass and carbon fiber materials form a beautiful unit in the preparation of the operating tool robot. At the same time, the robot's use of fiber materials provides an extensive design idea for architects.

2. CNC Operating composite materials

Thermoplastic polymerization resin

( Thermoplastic interactive booth)

It is designed and constructed by Baumgartner+Uriu(B+U) and SCI-Arc students. It consists of 233 different types of CNC milling machines. Each panel is made of a layer of polyurethane foam and thermoplastic polymer resin, which is only 1/8 inch thick. Sci-arc students first cut a foam template of 233 panels using a CNC milling machine, then poured thermoplastic resin into a template for cutting and painting. The join point of the panel is marked in the CNC template processing and connected with aluminum rivet. Assemble the panels into nine parts and then put them in place.

3.3 D Printer operating composite material

Polymer cement

( Emerging Objects Patented technology of invention —— Polymer cement 3D printing)

Polymer cement is a kind of high strength rigid material, which is enhanced by fiber and produces 3D printing materials stronger than traditional concrete. The products made of polymer cement are extremely lightweight, and the exterior finishes can be sprayed surface, matt finish or satin face, etc., can also be processed, frosted or painted.

Salt material

( 3D printing of crystal salt devices )

The salt comes from the San Francisco bay, where the salt is extracted from the 109-year-old salt crystallized pool in redwood city. The salt material is strong, waterproof and crystal clear. The designer used a powder-based z-corp 3D printer to print 336 transparent panels. Each panel is made of salt and can be rotated at will to synthesize a larger structure. The final combination forms a rigid shell, which is supported by a lightweight aluminum rod. The natural characteristics of salt allow natural light to penetrate into the interior of the space and highlight the structure.

Liquid 3D printing material —— Photosensitive resin

Silicon valley company Carbon3D recently unveiled a new 3D printing technology that can be printed directly, continuously and quickly in a liquid. It has upended the 3D printing process that has been stacked on top of each other over the past few decades, increasing the speed by 25 to 100 times and printing a number of unprecedented geometric shapes.

Ordinary 3D printing is actually "2D printing", and the liquid resin is usually stacked layer by layer. In other words, after printing a layer, wait for it to solidify, then proceed to the next layer of printing, and then glue the layers together. The edges of each layer tend not to be completely smooth, so the whole looks rougher. The edges of each layer tend not to be completely smooth, so the whole looks rougher.

The working principle of photosensitive resin: The CLIP technology developed by Carbon3D has not only increased the speed by dozens of times, but also has a smooth and delicate surface. The principle of CLIP is very similar to that of photocoagulation technology, which uses photosensitive resin to produce polymerization reaction and solidify properties under certain wavelength ultraviolet radiation. But it also takes advantage of another property: oxygen inhibits the curing of photosensitive resins. The balance of the two is the key to the success of CLIP technology.

The secret is at the bottom of the CLIP printer. There is a Window at the bottom of the sink, which is unique in that it is known as the Oxygen Permeable Window. There is a liquid photosensitive resin in the tank, and there is a uv projector under the sink. Oxygen can inhibit the curing process of photosensitive resin. Therefore, at the bottom of the tank of liquid resin due to exposure to oxygen become curing "blind spots" (dead zone) to keep the liquid, forming a layer of liquid film thickness. (about 2 ~ 3 red blood cells. This film cannot penetrate oxygen, but it can penetrate through ultraviolet light, so the upper layer of liquid resin in low oxygen state can be solidified under ultraviolet light. In this way, no cured resin is attached to the bottom plate. As the print platform goes up, more low-oxygen resins are sucked down to the bottom. The printing process can be carried out continuously and quickly, just as it "grows" out of a liquid, and does not need to be layered and solidified like traditional methods.

The numerical control mechanical operation composite material requires the architect to have the design and aesthetic sensitivity of multi-angle of materials, and can master advanced digital technology. The principle of operating the compound material by nc machine is far away from the traditional construction concept, and can directly rely on the three-dimensional model to construct the entity. No template is required to deal with complex geometry with high degree of freedom and precision.

No.3 Smart materials

The "artificial intelligence" discipline was first proposed in 1956. In the subsequent development, the concept of artificial intelligence was also applied to building materials. Scholars hope that building materials will be able to adapt to the surrounding environment as organisms do. The response, recognition and repair functions of the external environment are reflected by the changes in the external environment. In November 1989, at the Japan science and technology hall aviation, electronics and other technical review meeting, Japan Shun takagi professor proposed the concept of intelligent materials. In the same period, the study on the adaptive structure and smart structure of sensor function and executive function in aviation and space is also very active. As a result, they are increasingly known as intelligent materials and intelligent systems.

Through traditional materials and composite materials, the idea of intelligent materials originates from bionics (bionics is a tool that imitates the unique functions of creatures in nature to make human use, including imitating a dragonfly to make a plane. Its goal is to develop a material that makes it a "living" material with a variety of functions similar to living things. Therefore, intelligent material is a kind of new functional material that can sense external stimuli, can judge and properly handle and can execute itself. It must have the three basic elements of perception, response and control.

The emergence of intelligent materials has gradually eliminated the boundary between functional materials and structural materials in the traditional sense, and realized structural functionalization and functional diversification. The characteristics of the intelligent material itself and the concept of artificial intelligence are conformed to the internal relationship of the object and the self-adaptation of the building itself. Therefore, intelligent materials, as the implementation carrier of digital construction, have been extensively studied and used by scholars in recent years, especially in the aspect of building skin.

Intelligent materials can be divided into two categories:

Embedded smart material. In the matrix material, three kinds of raw materials with sensing, action and processing function are embedded. The sensing element collects and detects the information given by the external environment, controls the processor's command and excitation driver components, and performs corresponding actions.

Autonomous intelligent materials.

Some of the material's microstructures themselves have intelligent functions that can change their performance as the environment and time change, such as self-filtering glass.

1. Embedded smart material

Translated Geometries

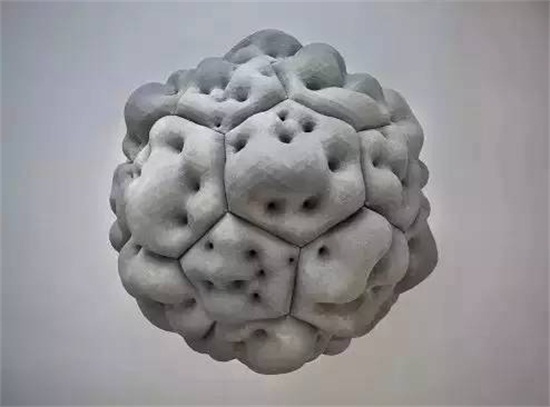

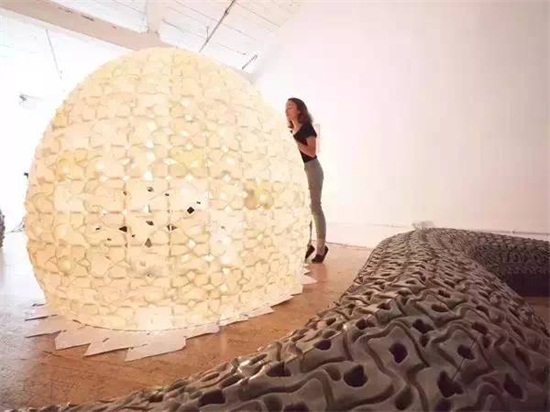

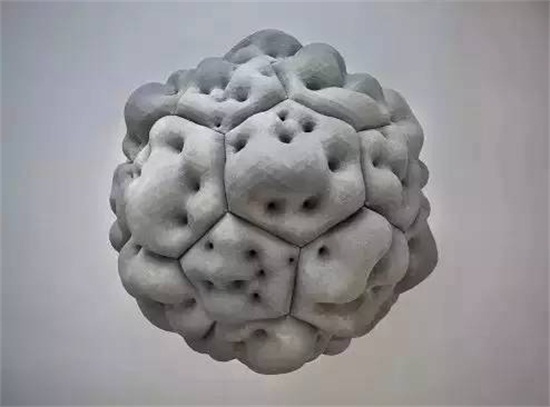

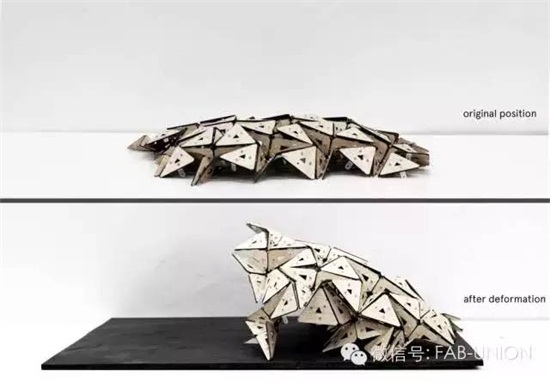

( Translated Geometries Material system)

IAAC master Ece Tankal, EfilenaBaseta and Ramin Shambayati are interested in "deformed architecture". They developed a new material system, Translated Geometries, for structural nodes using thermal response polymers.

(Change with the change of temperature)

IAAC master Ece Tankal, EfilenaBaseta and Ramin Shambayati are interested in "deformed architecture". They developed a new material system, Translated Geometries, for structural nodes using thermal response polymers.

IaaC USES shape memory polymer (SWP) to establish an entity structure model, which can use the unique properties of materials to realize self-transformation. This particular material will be able to accept external stimuli, and more specifically, to induce a change in phase over a temperature of more than 60 to 70 degrees Celsius. After reheating, the material is restored to its original state. It is conceivable that this material is especially suitable for the creation of new movable nodes.

(The expansion and closure of materials)

To maximize the use of this material, the team needs to find the geometry that can be transported to the target site in a stationary state. This shape shall be capable of deformation or expansion into desired shape. The folding structure is the best choice for these purposes. This collapsible structure, coupled with the advantages of the shape memory polymer (SWP), has the potential to create mobile structures and structures to respond rapidly to changing needs.

A smart film of the Media-ICT building

( Media-ICT building)

The biggest feature of the Barcelona Media-ICT building, which was awarded WAF 2011 world architecture award, is the use of material technology. A curtain wall insulation system consisting of a special thin film coated with teflon (ETFE), a special film of the air cushion unit, similar to the curtain effect. It can filter ultraviolet rays, as well as outdoor hot sunlight, with a 95% transmittance and a blocking of 80 percent heat and a 25 percent reduction in carbon dioxide.

(Media-ICT building)

The name of teflon is polyfluoroethylene, and the film thickness is usually less than 0.20mm. It is a kind of transparent film material, because it has the function of resisting pressure, heat preservation, heat insulation, can breathe, self-cleaning, electroless, it has been used in many famous buildings. For example, the facade material of water cube, Beijing Olympic national stadium in 2008, is teflon material.

(Special film coated with Teflon)

The special film of the Media-ICT building facade has three layers of material. The first layer is transparent film, and the second and third layers are just complementary shapes. Because it can expand itself, it is also known as "breathable membrane". A total of 154 air cushion units are installed in the curtain wall insulation system, 104 of which can be controlled by the computer in order to change the state of the unit based on the path the sun is running on the facade.

2. Autonomous intelligent materials

Moisture responsive wood composite

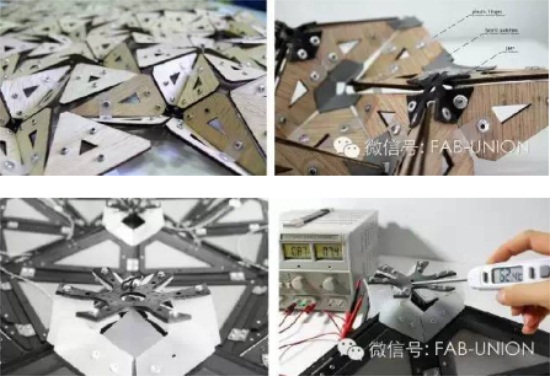

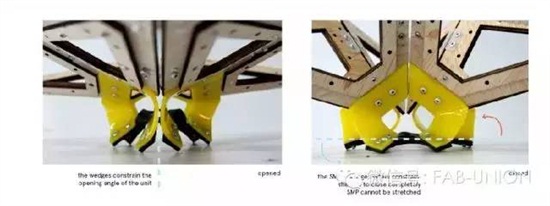

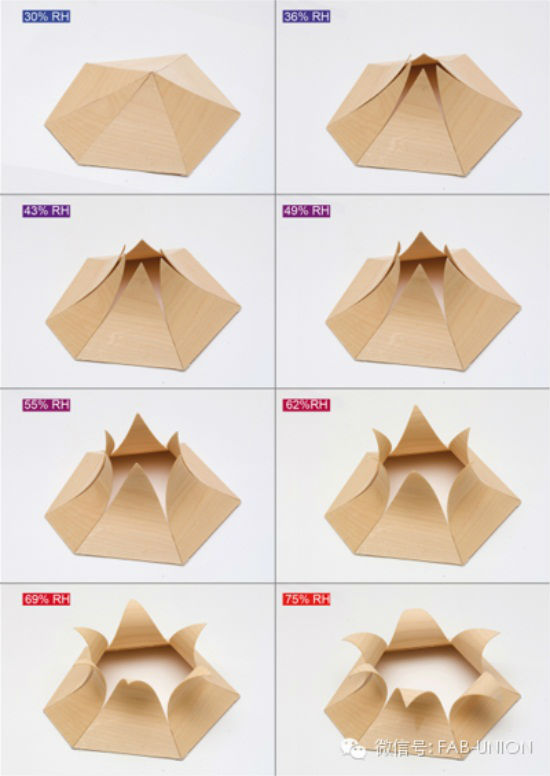

The ability to form conic surface with the inherent ability of the material is combined with the construction process of the seven-axis robot to construct the components of 28 different geometrical forms. The component is loaded with 1100 humidity sensitive holes. These holes can respond to changes in the range of 30 to 90 percent of similar humidity, which is equivalent to changes in humidity from sunny days to rainy days in moderate weather conditions.

The study makes wood, one of the oldest and most common building materials, a complex of climate responses. In the process of adsorption and release of moisture, changes in the distance between microfibers in the wood cell tissue were changed, resulting in significant anisotropic changes in size.

Water seepage ceramic

( As the water is absorbed the spherical hydrogel is also growing)

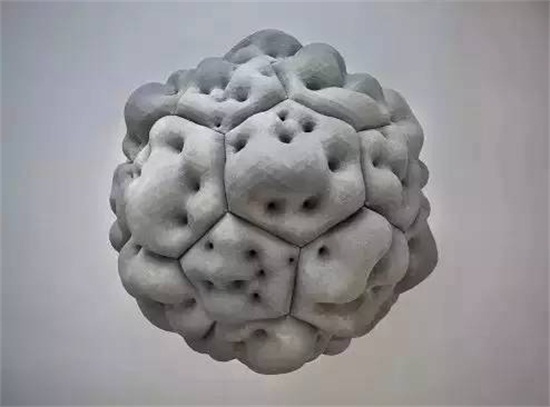

"Gel" is a substance that absorbs and retains 500 times its own weight. DMIC, of the Catalan college of architecture, uses sensitive materials to try to redefine "intelligence" and embed the "gel" into the building environment. Through the digital construction simulation, the construction technology design, and the perfect intelligent building system, thus enhances the building thermal performance.

(Surface permeable ceramic sample)

The control variables of clay, aluminum and acrylic acid were tested, and the multi-control concrete was determined as the carrier of hydrogel. The combination of the two materials is called "water permeable ceramics".

( Left: The final system consists of a clay layer and an intermediate layer of hydrogels and stretched fabrics.)

( Right: The final system consists of a clay layer and an intermediate layer of hydrogels and stretched fabrics.)

"Seepage ceramics", as an evaporative cooling device, reduces temperature and increases humidity, thereby reducing indoor air temperature by five to six degrees. Embedded intelligent system makes its performance proportional to the temperature of outdoor wind. In other words, when outdoor is hot, indoor temperature naturally decreases. At the same time, when there is no water evaporation, the system does not cool the interior space.

The intelligent material exhibits unprecedented advantages in architectural design and construction, and its appearance promotes the gradual unification of structure and function. At the same time, it also changes the traditional design method of architects, and considers the internal relations of buildings more, so as to further enhance the building's ability to adapt itself.