Why do the new buildings in foreign countries adopt the concrete pouring thick floor slab, even the wall is now watered?

The low-rise buildings in foreign countries are two or three storeys of buildings. The drawings often only see the blackened walls and rarely see the pillars. Don't they apply the framework? It is as if the concrete wall of the reinforced concrete, seldom used block to fill. This is not because only a small number of wonderful buildings are put on the Internet, so give us the illusion.

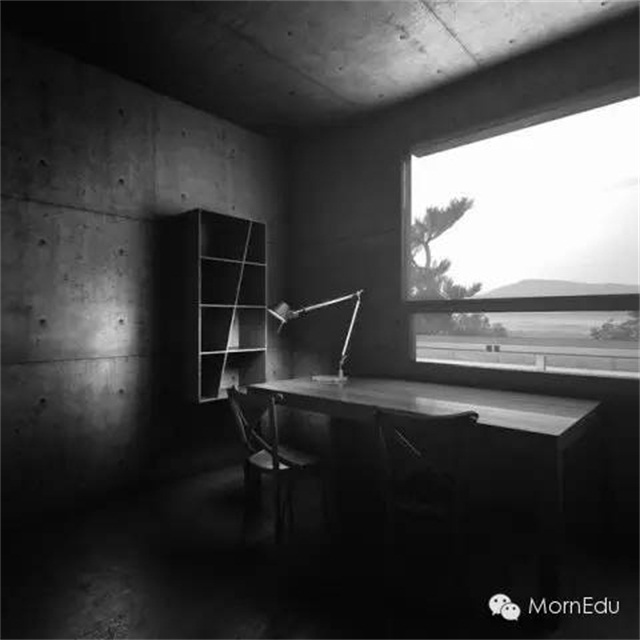

In fact, not only are these European buildings in magazines, you see the works of Mr. Ando, especially early works, almost all of them.

In fact, not only are these European buildings in magazines, you see the works of Mr. Ando, especially early works, almost all of them.

Look, all of these are cast-in-situ concrete, and still bare concrete. This kind of house, really only the Japanese can live.

If we have to classify them, we can call the structure of these concrete houses in the form of a low-rise shear wall.

Why not use frame structure? Why not build a wall?

On the one hand, it may be that the frame structure is not good. On the other hand, it may be that the lower shear wall is cheaper than the frame structure.

In some cases, the low-rise shear wall may be cheaper than the frame + masonry wall.

The cost of a building depends partly on the material, and partly on labor. We are accustomed to the "superior" social system, often only consider the cost of steel and cement, and forget the labor cost.

If labor costs are relatively low, such as at home, the cheaper option is to use as little and as much artificial structure as possible. For example, block filler wall, which is a piece of manual masonry by a worker. The concrete frame part should also pursue the most economical benefit, so the size of the beam column is not uniform. The cross-sectional reinforcement is also not uniform. This is a larger span. I use a 700 beam, and a rebar 5 square root of 25. The span is a little bit smaller, so I'm going to use 500 beams, 4 bars of steel, 20. The steel bars of each beam are not the same, but they are artificially cheap. According to the drawing, the steel bar should be gradually cut, and the steel bar should be placed.

If labor costs are high, such as in Europe or Japan, the cheaper option is to use as little structure as possible. Block wall? The worker is pure hand masonry? How much does it cost! It's too high-end! Ordinary people can't even think! The reinforcement of each beam is different? I hired the workers to go with the steel reinforcement, to pay their wages, than the savings of this kind of rebar money not know how many times!

So, industrialized, assembled steel structures, wooden structures, are very popular in these areas abroad. It only takes a few workers a few days to complete, eliminating the high cost of labor. Some highly industrialized structures, such as the wooden grille walls of North America, may not require professional workers. Buy the industrial production, the ready-made materials, find a few strong friends and relatives to help, can cover themselves.

This is the little house of these low-rise shear walls. The number of layers is generally very low, so the vertical load is not large, the axial compression ratio of shear wall is very low, and the horizontal seismic force is not big. You don't even need the edge components, just the uniform distribution of reinforcement. The floor is the same, the thickness is the same, the basic construction of reinforcement. The template is set up, and it does not require complicated artificial lofting, blanking, and reinforcing steel. It is the same. The same reinforcement is arranged evenly.

In fact, there are also such low-rise shear walls in China, for example, the most expensive luxury house in Beijing, as shown in the news, is obviously used to create a wall-to-wall shear wall.

On the other hand, if the design and construction control is good, the frame structure + block fill wall can also achieve the same effect as the European buildings in the magazine.

For example, A+B residence in Wang Yun's lushi villa in the following picture should be used as A common frame and block wall in China. But because the control is relatively good, so can achieve such effect.

As to the question of floor thickness, in fact, under the premise of meeting heat preservation, sound insulation, fire resistance, corrosion resistance and so on, the floor slab is too thick on the basis of structural stress. Under normal span condition, 100 and 120 thick cast-in-place floor slab is enough to meet the standard of rigid floor.

So why are some European buildings so thick?

In many cases, thick floor boards are used for vertical wall conversion. At this time, the vertical and horizontal loads of the unaligned walls are passed and redistributed through the floor. Therefore, the concrete floor needs a very large thickness, the structure needs to bear a large amount of additional vertical and horizontal load, the upper structure and the foundation cost will be increased. Or it's sacrificing structural performance in exchange for specific space and aesthetic feelings.

I am an architect, can I ask my structural engineer to make such a sacrifice? Of course, there are many cases of thick plate conversion in China.