Traditional buildings produce 800 tons of construction waste per 10,000 square meters. In front of the impact and environmental protection of 3D printing, it is better to apply it actively.

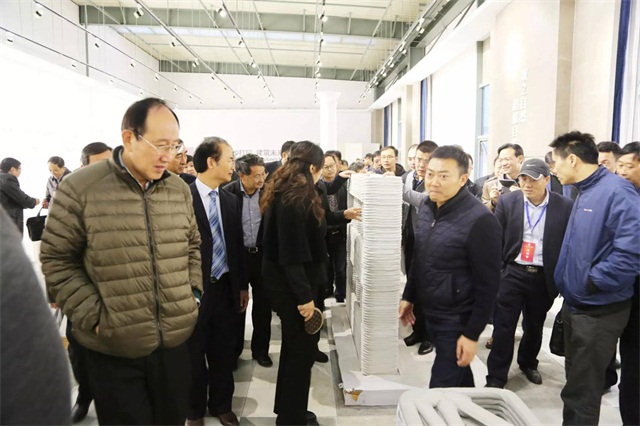

“Traditional buildings produce 800 tons of construction waste per square meter.” This striking number is the focus of the "13th China construction enterprise summit forum" in Suzhou on November 24th. A group of 300 people from the construction of some provincial and municipal departments, industry associations and construction enterprises of leaders felt that traditional construction companies can no longer continue to make construction waste after visit Yingchuang 3D printing architecture factory.

The forum was approved by the ministry of housing and urban-rural development, and co-sponsored by the China construction newspaper and the Jiangsu provincial housing and rural construction department. Forum specifications and levels are enough to guide future architecture. Gu Xiaoping, secretary of the party committee of the ministry of housing and urban-rural development in Jiangsu province, Qu Jian, president of China construction newspaper, as well as Li Bingren, president of China architecture decoration association, attended the forum and gave a speech. Forum participants gave a thumbs-up to the 3D printing technology of yingchuang's invention. Yingchuang 3D printing architecture technology be manufactured digitally and automatically print buildings. Compared with traditional company, it can save more than 30% raw materials and 50% construction cost. Moreover, it does not produce any construction waster and dust. Traditional construction companies can not achieve "Zero garbage".

This great technological invention shocked all the guests. They all praised with the world first 3D printing three-storey villa and the world's highest 3D printed residential six-story buildings. They said they would speed up cooperation with Yingchuang.

There is no environmental damage in the process of construction by 3D printing architecture technology. It can be said that 3D printing construction technology does not need to open mines to destroy the environment, but to rebuild urban mines. The construction of "garbage" in urban construction is used as inks for green construction, and the interior and exterior decoration can be realized synchronously, and all technical indexes conform to the related technical standards of the building. Safe, reliable, efficient and graceful construction was fully affirmed by the leaders and guests at the meeting.

The participants said that construction companies could no longer destroy the environment and make garbage. Whoever first uses 3D printing to print construction technology is the biggest winner. It is understood that Yingchuang 3D printing construction technology has been applied by many consortiums, governments and construction companies at home and abroad. (Rong Ping)