One minute to understand 3D printing architecture

One minute to understand 3D printing architecture

Winsun 3D printing architecture technology explanation

What is 3D printing architecture?

The 3D printing of prefabricated buildings completely overturns the noisy, dusty house that can be lived with interior, exterior decoration, insulation, electromechanical and structural integration.

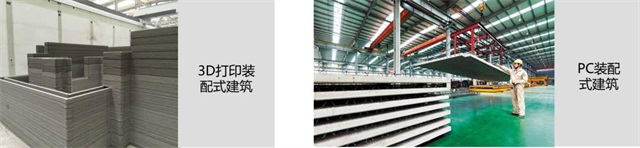

The difference between 3D printing prefabricated building and PC prefabricated building

1. The PC assembly building needs molds, while 3D printing prefabricated building do not need

3D printing prefabricated buildings are more flexible and can be customized for us. PC prefabricated buildings require very expensive steel molds, which are approximately 10000~13000 yuan/ton. With more than 100 USES, the cost can be reduced substantially. PC buildings must have high standards to have economic benefits.

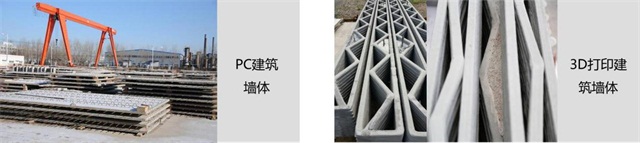

2. 3D printed prefabricated buildings require less space than a PC assembly building

PC assembly building is flat ground production with big production floor area and large investment.

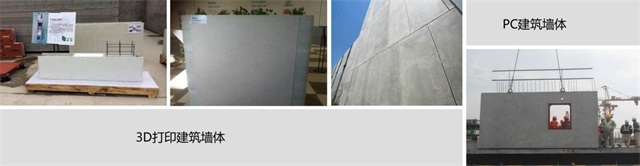

3. The production of 3D printed prefabricated buildings is more energy efficient than PC assembly building and can avoid PC defects.

PC prefabricated building is a production method with solid casting, which can not be made into an empty stomach structure, which is a waste material. Therefore, PC assembly building is 10%~30% higher than the traditional construction cost. The PC assembly building needs to be installed in a hoisting way, which has a high requirement on the strength of the product. Therefore, the amount of steel reinforcement used in PC building is 10%~20% more than that of traditional buildings. The non-load-bearing structure of PC assembly building adopts the adhesive method, so there are unavoidable defects such as water seepage. The building components printed in the 3D printing prefabricated building are hollow, the hollow building components are light weight and the steel quantity will be reduced. Printing building components can be integrated after assembly, so the integrity is very good, avoiding the problem of PC seepage.

4. PC prefabricated building components cannot achieve the integration of interior and exterior decoration insulation

PC prefabricated building components cannot achieve the integration of interior and exterior decoration insulation, requiring secondary decoration and insulation. And 3D printing prefabricated building components can be directly integrated into decoration and insulation, eliminating the labor and cost of secondary decoration and insulation.

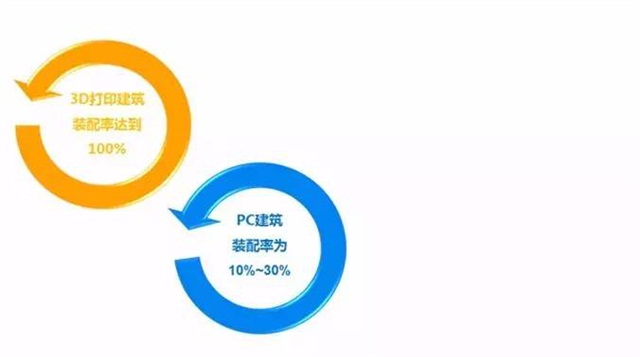

5. PC assembly building countries have assembly rate restrictions.

Currently, the assembly rate of PC assembly building is 10%~30%, and the country's installation and acceptance stipulates that the edge structure, constraint structure and core tube need to be cast on site. However, there is no limitation on the assembly rate of 3D printed prefabricated buildings, and the assembly rate can reach 100%. In addition, the bearing structures such as edge structure, constraint structure and core tube structure can be printed out in 3D printing and then cast in the field, eliminating the process of supporting the template and removing the template.

In the end, the two prefabricated building methods, PC assembly building and 3D printing assembly building, can be combined to form advantages and complement each other.