Winsun cooperates with Jiayuan to fully promote 3D printing green buildings

In May 2015, the state council issued the "made in China 2025", a strategic document for manufacturing powers, which designed the top-level planning and road map for China's manufacturing industry in the next decade. The papers confirms that regards information technology and manufacturing technology deeply integrated network intelligent manufacturing as main line to deepen the restructuring of the manufacturing sector and fully implement green manufacturing. This means that China will develop from a "manufacturing power" to a "intellectual powerhouse".

In August 2016, the ministry of housing and urban-rural development of the People's Republic of China issued the "outline for the development of construction industry informationization for 2016-2020" with new instructions for 3D printing: “Actively carry out research on 3D printing equipment and materials in construction industry. In combination with the application of BIM technology, this paper explores the application of 3D printing technology to construction parts and components and demonstrates application.”

Yingchuang Building Technique (Shanghai) Co.,Ltd is a high-tech enterprise that first achieves 3D printing build in the world.

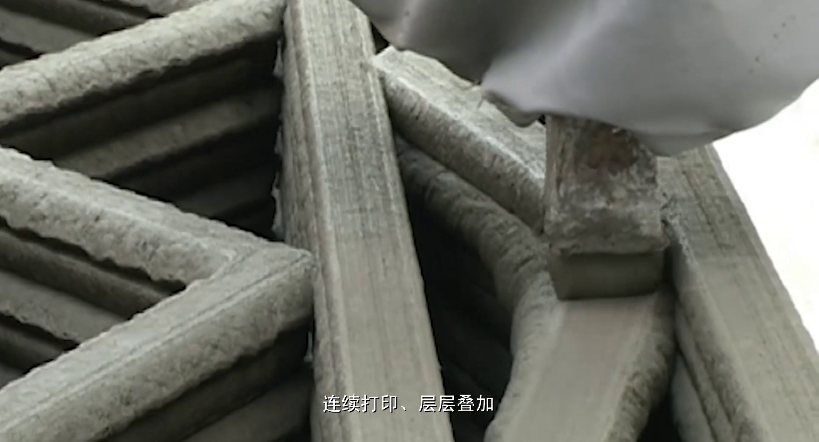

Yingchuang 3D printing architecture fits the concept of "smart manufacturing", which can be used to input the 3D housing data into the computer and the 3D printer can print the building walls in accordance with the instructions. The entire printing process is completely controlled by computers, which can save a great deal of manpower and material resources without any waste. This technology is a tool to realize the intelligent manufacturing of construction industry and real estate industry.

And the printing technology is the true green production way, which achieves the ideal standard of saving time, manpower, cost, energy and environmental protection. Taking Yingchuang 3D printing a building of 1100m² as a example, compared with traditional construction, 3D printing can save three-fourths of production cost and increase material utilization from 5% ~ 5% to 85% ~ 90%. The production cycle is only a third of the traditional architecture and can save 60% energy, which greatly improves the reliability of building houses, consistency and accuracy.

In 2015, Yingchuang 3D printing building went from scientific research to market. Dubai government office building, Shandong Binzhou Yingchuang 3D creative industrial park,grand yangshan scenic public toilet has been built and put into use; In 2016, Yingchuang reached cooperation intention with domestic and international regions, such as Shanghai, Zhejiang Lishui, Jiangsu Suqian, Hainan Haikou, Inner Mongolia Baotou, American super high iron, Dubai, Saudi Arabia, Israel, Iraq...

In the near future, Yingchuang will cooperate with well-known domestic developers to open the era of "intelligent manufacturing" in China's construction industry and real estate industry.