Revenue growth in the 3D printing industry is expected to grow by more than 50% this year

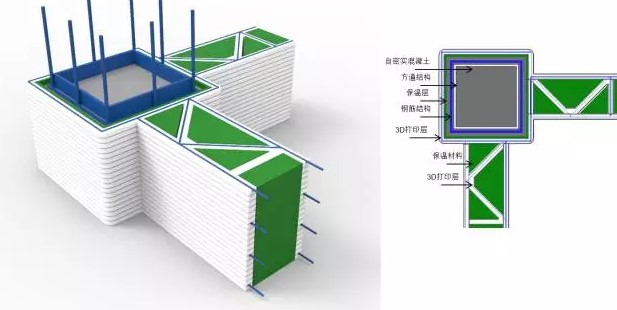

Yingchuang 3D printing steel structure house, full steel structure and 3D printing of the permanent stone veneer and strong earthquake resistance solve the steel structure fire, waterproof, anti-corrosion, sound insulation.

3D printing of the steel bone structure enclosure assembly building system A

3D printing of the steel bone structure enclosure assembly building system A

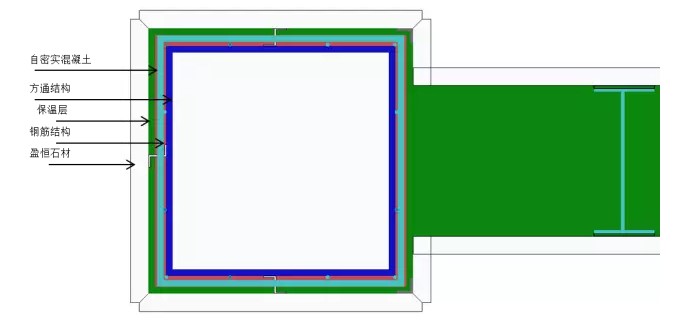

3D printing of the steel bone structure enclosure assembly building system B

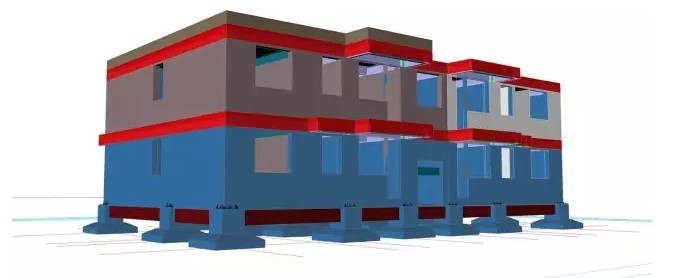

3D printing steel structure house

With the unprecedented pressure on energy conservation and emission reduction and the promotion of low-carbon economy and sustainable development, steel structure housing has attracted wide attention from all sectors of society. What is the value of the steel structure housing design?

First, realize low-carbon construction and sustainable development of residential buildings

Steel structure housing is the green building in the 21st century, which is an effective way to reduce carbon emission and promote the sustainable development of circulation in China.

Low carbon construction: the CO2 emissions is about 480 kg / ㎡ to build steel structure housing, lower 35% compared with traditional concrete carbon emissions by 740.6 kg / ㎡

Saving material: steel structure residential building weight is about 900-1000 kg / ㎡, traditional concrete is about 1500-1800 kg / ㎡, its weight reduce about 40%.

No wood templates and scaffolds are needed in the construction of steel structures. If its market share increases by 5 percentage points, it can reduce the amount of wood cutting to 9,000 hectares of forest

It can greatly reduce the consumption of such resources as cement and sand, thus greatly reducing the carbon emission in mining, smelting and transportation.

The construction self-weight loss, and save about 30% of the underground pile foundation;

Water saving (reducing sewage discharge) : the steel structure housing is the main construction site, which can significantly reduce water and sewage discharge during construction. If its market share increases by 5 percentage points, it will reduce sewage discharge equivalent to 10 west lake total water.

Energy saving (energy operation saving) : the CCA lightweight grouting wall has a good self-preservation function, which is three times the insulation performance of traditional brick walls, and greatly reduces the energy consumption.

Provincial land (improving the efficiency of land use) : the steel structure is "tall and light strong" and easy to achieve high-rise buildings, which can improve the efficiency of land use in unit area. The rate of indoor housing is increased by 5% to 8%, and the underground garage parking space can be increased by 10% to 20%. The social and economic value of the housing is especially prominent today.

Environmental protection: assembling construction, reducing noise from construction site, waste water discharge and dust pollution; Reduce sand and stone mining and construction waste discharge; Protect the environment; Creating a new era of construction civilization;

The recovery and regeneration of main materials: when the building is demolished, the recovery rate of the steel structure residential main structure is more than 90%, which is about 60% less than the traditional concrete waste discharge.

To respond effectively to the national call for "circulating mode of production", and the recycling and recycling of steel can be a strategic resource reserve for the state; Reduce the amount of waste in construction waste landfill to land and underground water source pollution (construction waste accounts for 40% of total social waste);

Reduce the amount of waste in construction waste landfill to land and underground water source pollution (construction waste accounts for 40% of total social waste);

The industrial waste is used as the main material in the composite wall, and the CCA wallboard is the main material of quartz sand tailings. The light quality grouting material is used as the main material for industrial wastes such as fly ash to effectively responds to the call of the state to "promote the utilization of industrial waste resources".

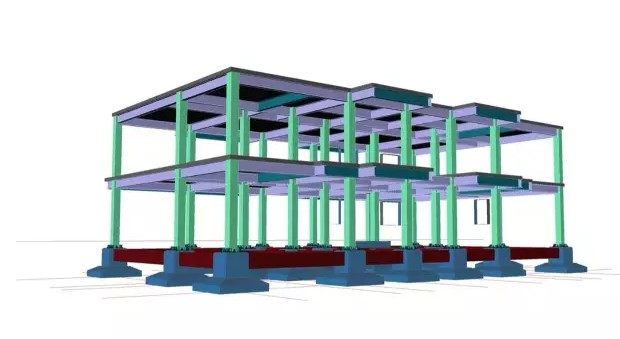

Promote the transformation and upgrading of the housing industry

Steel structure housing is completely in line with "standardized design, factory production, assembly integration of construction and decoration of the housing industry modernization development”, which is an effective way for our country to bid farewell to the era of hand masonry, to promote the change of residential building production mode, and to promote the transformation and upgrading of residential buildings and sustainable development.

Standardization of architectural design:

Complete technical specification for steel structure, design software, and the steel structure component size is accurate, so easy to implement "building in harmony with the component module and size", so as to improve the efficiency of design and construction.

The structural members of steel structure are generality and interchangeability, and adapt to the construction and industrial construction requirements.

Factorization of component production

Due to the precision prefabrication of most parts and components in the steel structure house, the processing precision and quality are unmatched by traditional field operation.

On-site construction workers are transformed into assembly workers, reducing the labor intensity and quality of workers.

Site construction and assembly:

All the structural components of the steel structure are completed in the prefabricated factory. The construction site will connect and assemble the components in a reliable way, such as bolts and welding, and build a house like a car.

All kinds of processes can be intersected to improve the construction efficiency and shorten the construction cycle by more than one third;

A large number of dry operations replace wet work, and the construction of on-site construction is greatly reduced, and the pollution emission is significantly reduced, with the general saving rate of more than 20% and the water saving rate of over 60%.

Few hidden projects, easy quality control and supervision, which can effectively avoid the problems of traditional construction, or the construction personnel's lack of responsibility to lead to quality security risks;

Assembly construction method occupies less construction site;

Greatly reduce the number of on-site operations and the number of on-site construction and management personnel, which effectively solve the problem of "shortage of migrant workers";

Relevant supporting advanced building energy-saving technology is more convenient to use.

Integration of construction and decoration

The surface of CCA board wall is very smooth and does not need to be plastering

The wall adopts the frame structure system of light steel keel, which is easy to be buried in pipelines, easy to realize the integration solution of building decoration, and reduce waste of resources and materials;

Integrated embedded decoration technology improves the quality of residential decoration.

Improve the quality and comfort of the house;

Improve the leakage and cracking of traditional residential walls;

The acoustic performance of the wall is improved effectively;

The overall grouting composite wall of CCA board with self-insulation function is used to avoid the disadvantages of external insulation of external walls or the poor fire resistance of the internal thermal insulation system (e.g., CCTV, Shanghai and Shenyang fire);

Non-dew and respiratory function CCA board grouting wall, provide dry, comfortable living space;

The doors and Windows are open without restriction, which improves the lighting and ventilation performance of the house and enhances the comfort level of the house;

There are no load-bearing walls in the set, the layout of the large open space. The space is easy to separate and realize functional transformation, improve the adaptability of the house to the family structure change, and extend the service life of residential buildings.

Improve the earthquake preparedness and disaster prevention capacity of buildings and build safe homes

Since 1900, the death toll from earthquake disasters in China has reached 550,000, accounting for 53% of the global total. The reason of this is that, for a long time, the construction of residential buildings in China is dominated by masonry structure or brick masonry structure. Most of victims were suffocated in the earthquake. The second is that the collapsed buildings block the road and seriously impede post-earthquake rescue efforts.

As one of the world's most earthquake-stricken countries, the Japanese government has been determined to improve its earthquake-resistant capacity after the earthquake in 1923. In the following year, the world's first building seismic codes were introduced, and the seismic performance of each building was calculated accurately.

Especially after the Kobe earthquake of 1995, 83.3 % of the deaths were caused by the collapse of houses, and 12.8 % were caused by fire. Subsequently, the epicenter of Hyogo prefecture carried out the "not dead birds" plan to require buildings to be subjected to an 8-magnitude quake.

The Japanese government put forward a "zero death" plan; In 2005, the central disaster prevention conference formulated the emergency response guidelines for building earthquake-resistant buildings. The earthquake resistance rate of buildings and their parts reached 90% by 2015.

Seismic performance is remarkable, therefore, the steel structure, all kinds of the most advanced shock means such as lightweight materials are widely used, and all of the old building almost all adopt the X, Y, K of different shapes, such as the steel structure framework for reinforcement.

The 3.11 earthquake, the highest level in the history of human observation in Japan, led to the subsequent wave of the tsunami. It turns out that Japan has indeed withstood the test of a magnitude 9 earthquake, which itself has not caused much damage to the building. The strength of the steel structure house has been confirmed again.

—- Yingchuang 3D printing classical case——

3D printing inside and outside the hardcover, 1100 ㎡ luxury villa (above)-- 3D printing reinforced concrete assembly building system

3D printing inside and outside hardback villa (above)--3D printing and reinforced masonry assembly building system

Real view of Dubai 3D printing office building (above)--3D printing and reinforced masonry assembly building system

A 3D printed 8-ton mobile hotel (above)--3D printing and reinforced masonry assembly building system

3D printing Chinese architecture (above)--3D printing and reinforced masonry assembly building system

3D printing Chinese architecture (above)--3D printing and reinforced masonry assembly building system

3D printed landscape wall (above)

3D printed sewage well (above)

3D printing septic tanks (above)